Table of Contents

Introduction

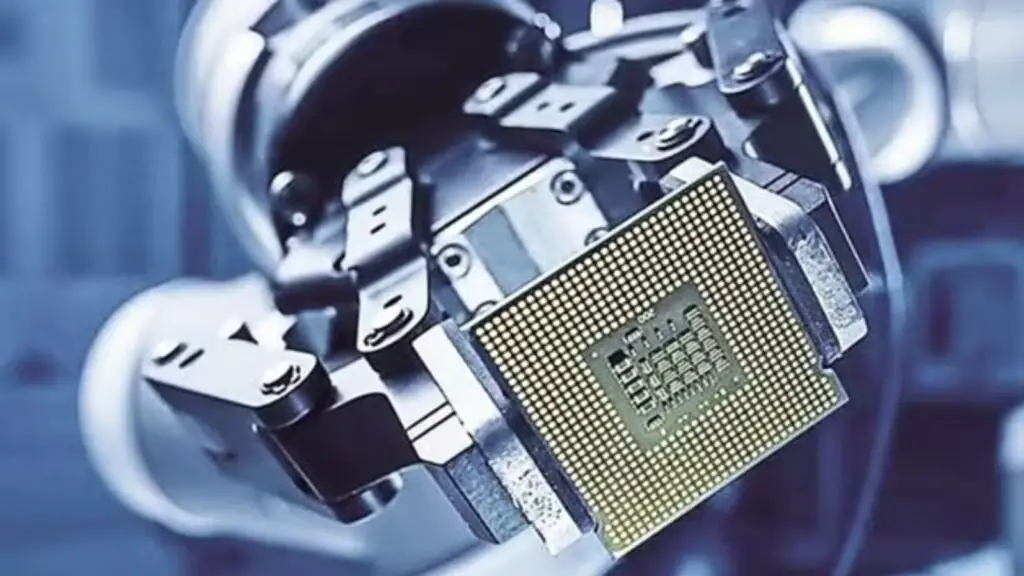

- India is already on the right track of achieving success in the semiconductor industry; it wants to become a dominant player in the industry.

- The latest one is the recent clearance to a new semiconductor assembly and testing by Kaynes Semicon of Rs 3,300 crore in Sanand, Gujarat, thus unlocking the nation’s dream project behind its back.

- This action is in line with India’s vision to develop the country’s semiconductor industry to become like the US, Taiwan or South Korea. But it is time to analyze what this new direction may hold for India semiconductor industry and consequently for the Indian economy and technologies.

A Step Forward in India’s Semiconductor Journey

- Semiconductor industry is an essential part of the modern electronics as it forms the base for all electronics products including consumer electronics as well as specialized industrial applications.

- The proposed plant of Kaynes Semicon is coming under the Rs 76,000 crore semiconductor manufacturing incentive scheme launched by the Indian government for encouraging the growth of semiconductor industry in the country.

- With a production capacity of 60 lakh chips per day, this plant will serve various sectors namely industrial purpose, automobiles and EVs, consumer electronics, telecom and mobile phones.

- The fact that the Union Cabinet has okayed this effort is yet another sign of this government’s determination to create an indigenous semiconductor ecosystem.

- However, the Su 56, also known as the fourth assembly unit and the fifth semiconductor unit, approved under this scheme, provides strategic directions to India expansion of the semiconductor units.

Why Gujarat? The Rise of Sanand as a Chip Hub

- Firstly, it was planned that the plant of Kaynes Semicon will be opened in Telangana. But, the move to shift the project from Gosha to Sanand in Gujarat is a clear indication of emergence of the region as a semiconductor manufacturing zone.

- The fact that the government hints it is wooing Sanand as a cluster for chip assembly plants was a clear pointer to its importance.

- Clusters break down barriers that make sharing of expensive resource like infrastructure and skilled labor possible thus encouraging collaboration.

- Sanand’s selection is due to standard procedure of distributing industrialization and its growth across several states of the country to ensure very to maintain a balance of industrialization across states.

- The creation of such a cluster is not only about providing employment to work DIRECTLY in the facility but also provides an impetus to related industries thus improving the economic structure of the region.

Government Support and Investment: A Catalyst for Growth

- Some of the privileges granted by the Indian government for the development of the Kaynes Semicon plant involves a subsidies grant in the tune of Rs 1,300 crore.

- This financial backing is important because semiconductor industry calls for enormous capital investment; on infrastructures, technologies, and human resources.

- This support is based on India’s long-term plan of bringing both Indian and global investors to invest in the semiconductor business in India. Earlier, the government has okayed facilities like Tata Electronics’ $11 billion fabrication plant with Taiwan’s Powerchip, Micron Technology’s assembly plant with Japan’s Renesas, and CG Power and others.

- These projects show India’s potential to lure the world’s best semiconductor manufacturers making it a viable hub for such industries.

The Global Semiconductor Context: India’s Strategic Positioning

- Globally, the automobiles industry is dominated by countries like United States, Taiwan, South Korea and China.

- These countries have real manufacturing capabilities backed up by R & D, people skills and good supply chain.

- India’s entry into this competitive space is driven by several factors:India’s entry into this competitive space is driven by several factors:

- Growing Demand: As a result of increasing pace of digitalisation the usage of semiconductors in consumer electronics, automobile segment and telecommunication segment is continually rising.

- Strategic Independence: Hence, through building semiconductor capacities, deepening India’s strategic autonomy is one of the objectives of India’s domestic semiconductor industry.

- Economic Growth: Semiconductors are essential in the economic development because of the high value addition, creation of high skill employment, and they also enable upgrading of the country’s technology.

- It also requires the ability to lure international investments/investment and technologies that are important in the establishment of a world-class semiconductor industry.

- From the partnership with leading international firms, direct foreign investment is delivered alongside technology and efficient processes.

Future Prospects: Phase Two of India’s Semiconductor Scheme

- The establishment of the Kaynes Semicon plant is among one of the projects that have been approved by the Indian Government in the initial reactions of its plan towards setting up semiconductor fab.

- Since almost all the $10 billion of subsidy under the existing scheme have been paid out, the government is preparing for second round and which could involve an apparently increase in the amount to $15 billion.

- The second phase it is believed to provide funding for raw materials and gases used in chip production which is one of the inputs in semiconductor manufacturing.

- Moreover, subsidies of assembly and testing plants may decrease from the current 50% to 30% for the conventional packaging technologies and 40% for advanced packaging technologies.

- This adjustment is used to get the right balance to the available resources where more focus is duly placed on innovative and high end sectors of the industry.

- Further, the government is also planning to decrease the subsidy on technology transfer expenses to push the companies to develop their technological development.

- This plan is aimed at developing a indigenous expertise in manufacturing and designing, and make India as a manufacturing and innovation destination.

Conclusion: A Bright Future for India’s Semiconductor Industry

- The setting up of Kaynes Semicon plant at Gujarat is a signal of the direction that India is headed towards achieving its dream of being among the world’s leading semiconductor manufacturer.

- Based on the government support and proper planning, India is now on the right track to address the development of an integrated semiconductor ecosystem.

- With the appreciable shift to digital and electronic solutions; the need for semiconductors will remain fashionable.

- This means that India is well-placed in terms of prospects to stake its claim on the processes needed to spur innovation and growth of the semiconductor industry in the global value chain.

- The effectiveness of these programs will remain contingent on that of the government for funding and continued collaboration and company research and development initiatives.

- Thus, India will be able to realize its aim to become a global manufacturer of semiconductors after refining the necessary conditions that encourage the industry’s development and the creation of advanced technology.

FAQS

Q1: What is the Kaynes Semicon chip assembly plant?

Ans: The Kaynes Semicon chip assembly plant is a semiconductor assembly and testing facility approved by the Indian government. It is being set up in Sanand, Gujarat, at a cost of Rs 3,300 crore. The plant will have the capacity to produce 60 lakh chips per day.

Q2: Why was the Kaynes Semicon plant approved by the government?

Ans: The plant was approved as part of India’s Rs 76,000 crore semiconductor manufacturing incentive scheme. This initiative aims to boost domestic semiconductor production, reduce dependency on imports, and position India as a global player in the semiconductor industry.

Q3: What applications will the chips from this plant cater to?

Ans: The chips produced at the Kaynes Semicon plant will cater to a variety of applications, including industrial automation, automotive systems, electric vehicles, consumer electronics, telecom, and mobile phones.

Q4: Why was the plant moved from Telangana to Gujarat?

Ans: The decision to move the plant to Gujarat was influenced by the government’s plan to develop Sanand as a cluster for chip assembly plants. Creating a cluster allows for shared resources, better infrastructure, and a supportive ecosystem for semiconductor manufacturing.

Wonderful web site Lots of useful info here Im sending it to a few friends ans additionally sharing in delicious And obviously thanks to your effort

Hi Neat post There is a problem along with your website in internet explorer would test this IE still is the market chief and a good section of other folks will pass over your magnificent writing due to this problem

I will definitely check.thank you so much.

I simply could not go away your web site prior to suggesting that I really enjoyed the standard info a person supply on your guests Is going to be back incessantly to investigate crosscheck new posts

Thank you so much for your kind words!

What i do not understood is in truth how you are not actually a lot more smartlyliked than you may be now You are very intelligent You realize therefore significantly in the case of this topic produced me individually imagine it from numerous numerous angles Its like men and women dont seem to be fascinated until it is one thing to do with Woman gaga Your own stuffs nice All the time care for it up